What to expect when making wine (includes kits and hedgerow/allotment):

Firstly your must can ferment at a different rate each time, even if you are making the same kit or following the same recipe due to factors such as temperature, oxygen and variation in sugar amounts. Some wines show very little sign of fermentation apart from a bowed lid on the fermentation vessel, some won’t even push bubbles through the airlock. In most cases this doesn’t mean that your brew isn’t fermenting, CO2 escapes through the path of least resistance so if there are any pin holes around the lid it can escape through, it will. Again this is nothing to worry about, an airtight fermenting vessel at this stage is unnecessary, some brewers don’t use an airlock at all but just place the lid on top of the vessel ensuring there is a small gap to allow CO2 to escape.

The only true way to know whether your wine is fermenting or not is with a hydrometer, take two readings over a 48 hour period and if they have changed ferment on until the readings are the same.

Fermentation Process:

It is best to brew wine at a temperature of between 20 and 26 degrees C and to keep this as constant as possible, but don’t worry too much if your temperature does fluctuate a little as it can be difficult to maintain the correct temperature at all times without a equipment like the Inkbird. However do watch out for a vigorous fermentation as this could effect the taste of the wine, this is due to the yeast producing unwanted enzymes that will affect the finished product. Cooler and therefore slower fermentations are much more preferable.

Wine goes through two fermentation stages the first or primary fermentation is sometimes described as aerobic and the second fermentation is sometimes called anaerobic which will be discussed below.

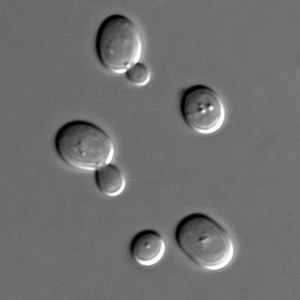

During primary fermentation, which can take between 4 and 7 days, oxygen is needed for the yeast to reproduce this is called aerobic fermentation. The yeast do not actually respire but use the oxygen as energy to reproduce through the process of budding, this is where a daughter cell forms on the parent cell and continues to grow until it separates from the parent cell. The more oxygen there is the more the yeast can reproduce. If there is not enough oxygen the yeast will struggle to reproduce and therefore the fermentation will not be as efficient, this is why giving your must a good stir before pitching the yeast will ensure there is enough oxygen in the brew for primary fermentation. During aerobic fermentation a small amount of alcohol is produced but most of the yeast’s energy is going towards reproducing. During primary fermentation a sachet of yeast suitable for a 5 gallon batch will multiply up to 100 or 200 times during the reproduction process. Once the oxygen is used the yeast moves onto using the sugars in the must as an energy source.

Secondary fermentation is much slower than primary as a lot of the action has already taken place, unlike primary fermentation it is best practice to limit the musts exposure to oxygen. By limiting the yeast’s exposure to oxygen it then starts to concentrate on the remaining fermentables using it’s energy to eat up and convert these into alcohol and CO2. Secondary fermentation is often referred to as anerobic fermentation due to the lack of oxygen.

Wine Yeast:

The most common yeast used in wine making is Saccharomyces cerevisiae which is also used in beer making. Only a few strains of this yeast are suitable for wine making. Final alcohol level depends on how much sugar is in the must and whether the yeast is allowed to ferment to dryness, if you prefer a sweeter wine then fermentation can be stopped at the desired sweetness which is a process commonly used with dessert wines.

Stuck Fermentation:

This is covered more extensively in another article but here are a few things to watch out for:

- Temperature too high: If the temperature goes over 26 degrees this could be too hot for the yeast which will kill it, you’ll then need to add a re-start yeast.

- Too cool: If the temperature dips below 18 degrees this will cause the yeast to slow down or go dormant heating the must back up to around 21 degrees should kick start it back into action.

- When making a hedgerow or allotment wine it is best to use yeast nutrient which keeps the yeast healthy and active. Alternatively you can buy wine yeast compound which is a mixture of yeast and nutrient.

- If you have used concentrate juice from the supermarket they can sometimes contain preservatives which kill yeast. Make sure to use those with out preservatives.

For more info on stuck fermentations see:

If you have any questions we’re always happy to help, contact us via email:

sales@home-brew-online.co.uk

or call us on: 01904 791600

Happy Brewing!

Right now I have some 25 Liters of mead brewing. I used regular wine yeast and some yeast nutrition salts for optimal performance. I almost had a stuck fermentation at the beginning due to a lack of oxygen which I solved by blowing air into the must using a bit of water hose.

Since then it keeps fermenting almost three weeks by now. Everytime I find the must turning sourly due to a lack of sugar, I add some honey and some table sugar.

What really astonishes me though is the fact that even though I measured about twenty percent of alcohol by volume it keeps on fermentig quite strong!

I only witnessed something like that by using turbo yeast and I never could have imagined that this was also possible with wine yeast which I believed to quit working somewhere between 14 to 16% ABV.

LikeLike

How do you stop fermentation?

Do you use sulfur?

LikeLike

I haven’t seen that before either because as you say you would expect the yeast to stop working once it’s top alcohol level has been reached, very strange. You can use fermentation stopper to stop the ferment which is Potassium Sorbate.

LikeLiked by 1 person